Twin Polymerization

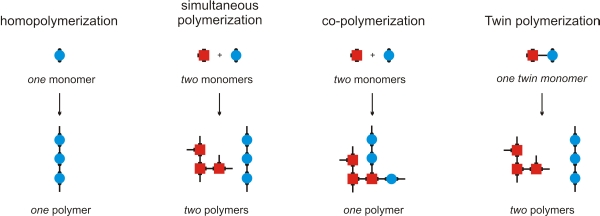

The principle of a twin polymerization is rather simple: a defined compound, the twin monomer, reacts in a single step to form two distinct homopolymers. In a way, this reaction constitutes the counterpart to the copolymerization:

However, having a closer look, twin polymerizations are complex processes. In a twin monomer the polymerizable building blocks are covalently bound in such a way that in a single step two (or even more) different polymer chains will form - coupled with each other mechanistically, temporally and spacially. The contemporary growth of several polymer chains occurs in a limited volume. Thus, theoretically, the polymer strands are placed next to each other on a molecular length scale immediately after their formation. If the rate of diffusion of these polymers is lower than their rate of formation, nanostructured hybrid materials arise on a definited time scale. Directly after polymer formation this nanostructure can be fixed using chemical as well as physical methods. Our studies to date show that it is possible to obtain inorganic/organic nanocomposites from defined twin monomers containing silicon, boron or titanium while the organic component comprises for example furfuryl alcohol or salicyl alcohols.

In addition to the known principles of polymerization (homopolymerization, copolymerization, simultaneous polymerization) we seek to establish the twin polymerization as a new type in macromolecular chemistry and materials science.

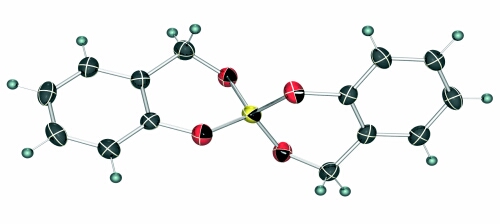

Using this method transparent phenolic resin/silica nanocomposites are obtained from a melt of the twin monomer 2,2\'-spirobi[benzo-4H-1,3,2-dioxasiline]. By simultaneous twin polymerization of different monomers, e. g. with 2,2-Dimethyl-4H-1,3,2-benzodioxasiline, the domain sizes and mechanical properties of those nanocomposites can be controlled as well.

| top left: | ORTEP drawing of the spiro-monomer.[5] - © [2009] Wiley - VCH |

| top right: | transparent nanocomposites obtained by simultaneous twin polymerization.[6] |

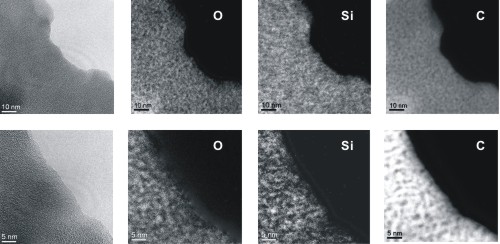

| bottom: | energy-filtered transmission electron microscopic image of a nanocomposite obtained by simultaneous twin polymerization. Light areas represent the respective element.[7] - © [2012] Wiley - VCH |

Selected publications on this topic:

| [1] |

Nanocomposites Prepared by Twin Polymerization of a Single-Source Monomer. S. Grund, P. Kempe, G. Baumann, A. Seifert, S. Spange, Angew. Chem. Int. Ed. 2007, 46, 628–632. DOI: 10.1002/anie.200504327 |

| [2] | Synthesis of nanosized TiO2 by cationic polymerization of (μ4-oxido)-hexakis(μ-furfuryloxo)-octakis(furfuryloxo)tetra-titanium. A. Mehner, T. Rüffer, H. Lang, A. Pohlers, W. Hoyer, S. Spange, Adv. Mat. 2008, 20, 4113–4117. DOI: 10.1002/adma.200801376 |

| [3] | Nanoscale Tungsten Trioxide Synthesized by In Situ Twin Polymerization. F. Böttger-Hiller, R. Lungwitz, A. Seifert, M. Hietschold, M. Schlesinger, M. Mehring, S. Spange, Angew. Chem. Int. Ed. 2009, 48, 8878–8881. DOI: 10.1002/anie.200903636 |

| [4] | Nanostructured Organic Inorganic Composites by Twin-Polymerisation of Hybrid-Monomers. S. Spange, S. Grund, Adv. Mat. 2009, 21, 2111–2116. DOI: 10.1002/adma.200802797 |

| [5] | Nanocomposites with Structure Domains of 0.5 to 3 nm by Polymerization of Silicon Spiro Compounds. S. Spange, P. Kempe, A. Seifert, A. A. Auer, P. Ecorchard, H. Lang, M. Falke, A. Pohlers, M. Hietschold, W. Hoyer, G. Cox, E. Kockrick, S. Kaskel, Angew. Chem. Int. Ed. 2009, 48, 8254–8258.'; DOI:10.1002/anie.200901113 |

| [6] | Simultaneous Twin Polymerization - Controlling the Nanostructure Formation of Hybrid Materials T. Löschner, A. Seifert, R. Lungwitz, G. Cox, A. Lange, H.J. Hähnle, S. Spange Macromol. Rapid Commun. 2011, 32, F60–F61. |

| [7] | A Modular Approach for the Synthesis of Nanostructured Hybrid Materials with Tailored Properties: The Simultaneous Twin Polymerization. T. Löschner, A. Mehner, S. Grund, A. Seifert, A. Pohlers, A. Lange, G. Cox, H.-J. Hähnle, S. Spange, Int. Angew. Chem., 2012, 51(13), 3258–3261. DOI:10.1002/anie.201108011 |